Risk Management for Commodity Traders Related to Inventory and Formula Pricing

Like all commodities, pricing is affected by a variety of factors and can be subject to tremendous volatility. Economic demand, environmental compliance regulations and industry changes all factor into uncertainty and therefore volatility. Producers and consumers of commodities face considerable financial risk without effective risk management strategies.

A robust commodity hedging strategy requires near real-time information of inventory positions. This can be a difficult prerequisite to fulfill considering the physical inventory may be under shipment or transport, inventory can vary in quantity or composition of the commodity and the nature of the product can be a secondary commodity with loose correlation to primary commodity price indexes.

Risk faced by both primary and secondary industries fall into three categories: inventory-based market exposure, formula pricing market-exposure and foreign exchange exposure. While manufacturers and processors must manage their exposure vis-à-vis inventory and their buyers, traders are sometimes tasked with managing risk on both the supplier and the consumer. For example: a trader would purchase a container on formula pricing and as well as sell it on formula pricing. The combination of market exposure risk, credit risk, liquidity risk and operational risk can be dangerous without an adequate strategy and management.

Risk Management Strategies:

Hedging and formula pricing are the primary methods to manage risk. Each method requires various management and governance to be effective and can become complex particularly for trading operations.

Hedging Physical inventory that is exposed to market price volatility can be offset through hedging in the futures market. Producers and consumers can eliminate risk by using an offset hedging strategy where producers will sell specific quantities for a specific delivery date and conversely consumers will buy for a specific date. Hedging in the future markets eliminates market pricing risk thereby stabilizing profit margins but at the same time, limits the opportunity to profit from favorable market movements. Locking in prices is generally a tool to protect and fix profit margins as future prices are locked-in on equal volumes and in opposite directions for a defined delivery date.

When a physical transaction on the material is executed, the hedge transaction is also liquidated at the prevailing cash prices. Therefore any physical losses incurred on the physical transaction will be offset by profits earned by the hedge transaction and subsequent liquidation. Conversely, any profits earned due to market price movement on the physical transaction will be offset by losses in the hedging transaction leaving the net profit of the expected fixed profit margin.

Formula Pricing Traditional fixed price contracts differ from formula pricing which allows the setting of prices subject to terms of the transaction. In essence, the price of the material will float is the market index until a specific event triggers a final set price. Common market indices such as LME are the basis for formula pricing for metal; contracts will stipulate the right to set a price and pre-determined volume.

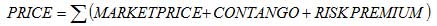

Fixed price contracts are predetermined prices considering contango and risk as follows:

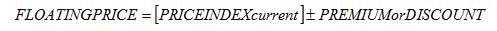

Formula pricing are floating prices on specified volume with specified time frames to set fix a price generally at the buyers discretion.

The buyer will typically have the privilege to set a price from the contract date to the delivery date of the material or shortly thereafter. However, it is often the case where the buyer will be allowed to set the price for a period of time after receiving the physical material in which case it is normal practice to collect the then value of the material plus an additional buffer. This buffer serves as a mitigant for credit risk if the market were to go against the buyer considering material has already been delivered.

In the base metal sectors, the use of these techniques may be used in a relatively simple method. In practical operations, inventory delivery and preparation are time dependent functions and actual transacted material often has nonlinear correlation and composition to base metals pricing. Mismanagement can be a very costly mistake.

Management of Risk Strategies:

There are several fundamental requirements to effectively operationalize an effective risk management programs as follows:

- Inventory Position Monitors: Producers, Consumers and traders require accurate and reliable inventory data to make sound decisions. Volume reporting must be agile to accommodate variation in actual versus contractual quantity of material received or sold. It is imperative that the inventory monitors are real-time systems so as to capture new or executed contractual obligations or anticipated inventory movements.

- Material Composition and Correlation to Indices: Volume reporting must accommodate scenarios when the material does not correlate perfectly to a base-metal index. This is often seen in the recycling sector and can affect the volume of the hedge. The quality of the alloy or the scrap metal may be comprised of several base metals and therefore affect the nature of the hedge transaction.

- Managing Delivery Latency: Inventory monitoring systems must report inventory movements by delivery or execution date. Systems with poor reporting on expected time-frames of inventory movements may cause improper hedging delivery dates and ultimately cause cash liquidity issues. This can be simplified if transportation systems such as marine freight are integrated into hedging decision making and reporting.

- Accounting and Mark-to-Market Gains and Losses: the complexity of financial accounting for hedging operations requires a robust financial platform to reflect the true value of inventory – both physical and hedge inventory. The fluid nature of commodity price indices requires systems that will report and alert management of gains and losses from market price movements and using fair-value accounting standards, reflect impacts of market price movements consistently and accurately on financial statements.

- Transactional Profitability Tracking: market price movement may cause specific transactions to exhibit hyper-profit which is offset by losses on the hedge transaction (or vice-versa). Management reporting must account for this to provide visibility of the true profit margin of any transaction.

- Managing Credit Risk of Formula Pricing: Under scenarios such as formula pricing contracts that allow the buyer to set prices after delivery of materials exposes credit risk. Typically, the terms of such a contract impose the buyer to pay more than 100% of the value of the contract (e.g. 120%). This additional amount is effectively a sort of margin deposit to withstand any mark-to-market revaluation losses of the inventory. It can very well be the case that the market may move more than the buffer collected leaving the transaction losses. In order to withstand such credit risk, margin collateral management is required to track situations where a margin call must be made failing which price fixing prior to any loss incurred.

- Managing Liquidity Risk: Hedging counterparties will collect margin collateral prior to offering a trading line. If there is a significant swing in market prices, a margin call may ensue creating cash flow impact. Liquidity issues can also arise if the delivery dates of contracts are mismatched as compared to their respective hedges. Commodity hedging requires sufficient functionality to report on margin and cash flow management. In addition, capital restrictions will in turn limit the amount of margin and thereby limit hedging counterparty trading lines. Ultimately, up-to-date and accurate information needs to be reported to manage cash-flow and trading lines